weld charpy impact test|charpy hardness test : agency The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the . web15 de jul. de 2020 · Daria is a smart and sarcastic girl who deals with the idiocy and hypocrisy of her school and family. IMDb provides information on the show's episodes, .

{plog:ftitle_list}

Resultado da O Classificados X disponibiliza aos seus visitantes a maior lista de classificados de convívio e anúncios de acompanhantes em Portugal. São .

The Charpy test is a standardized procedure designed to measure the energy absorbed by a material during a sudden impact load. This evaluation method assesses the material's resistance to fracture under impact conditions, offering valuable insights into its toughness and impact .Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa.

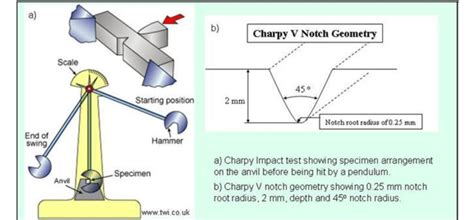

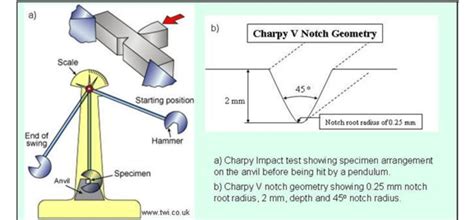

The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the .Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .The Charpy V Notch (CVN) test is a basic method for defining toughness and, in this process, toughness is defined in “joules or ft lbs” at the “temperature of test”. There are other, more complex methods but the CVN test is cheap, is a good .The Charpy V-Notch test is the welding industry’s most common method of measuring a weld’s toughness and involves multiple steps — from preparing a test plate to cutting and baking sample blanks, adding a notch to the specimen .

Before you learn what is Charpy V Notch Impact Testing, it is important to understand Toughness as a material property because impact testing or also called CVN testing is the only test used to measure the impact .

charpy v notch testing

There are 2 types of impact tests: the Izod test and the Charpy test. The Izod test is used to determine the amount of energy required to fracture a metal sample. The Charpy test is used to determine the amount of energy . Charpy impact testing, or V-notch testing, is an evaluation of a material’s strength and performance under impact conditions. It involves a pendulum with a pointed hammer on the end swinging and hitting a machined .The Charpy V-notch test is one of several tests to determine impact toughness in filler metals and is considered the industry standard. . A computer calculates the CVN impact value by measuring the highest point of the pendulum after . The Charpy impact test, also commonly referred to as the Charpy V-notch test by material scientists, serves as a standardized high-strain rate examination to quantify the energy absorbed by a material upon fracture. The .

For example, when impact tests are required as part of the classification of an electrode, they are machined from the same test weld as the tensile specimens. The test plate is 20 mm thick and the impact specimens are located mid .

charpy v notch impact test

Fabricators often find significant differences in Charpy impact property test results with the same welding materials, plate and welding parameters. We encountered this situation a number of years ago when exploring significant impact property differences in multipass welds that were made with processA widely employed method for assessing weld toughness and impact resistance is the Charpy test, also known as the Charpy V-notch test. This article provides an in-depth exploration of the Charpy test, covering aspects such as the test machine, specimen preparation, temperature variations, test results, and the advantages of this evaluation .

The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is abruptly subjected to bending stress. The specimen is usually 55 mm long and has a square cross-section with an edge length of 10 mm.

when the anticipated temperature (ambience or media) in an oil and gas facility is not going to go below -20F is Charpy impact testing required for the weld procedure? 1. For API wellhead welding to ANSI line pipe, MDT above at -20F 2. Same as 1 above but MDT below -20F 3. B31.3, 31.4, or 31.8 piping with MDT above -20F 4. The Charpy impact specimens were cooled down by an ethanol-dry ice (solid carbon-dioxide) bath kept at the test temperature. In order to establish the repeatability of the test results, experiments were conducted at least three times for each sample. Figure 9 shows the Charpy impact specimens after fracture testing.

The Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away from the pendulum hammer and is placed exactly across from the point at which the hammer strikes the specimen. This paper presents the results of the Charpy V-Notch (CVN) impact test for the ST, TL, TS, LS, LT, 45°, and SL directions in API 5L X52 pipelines with electric-resistance-welded (ERW) and .Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. . Requiring Charpy-V notch (C v) testing of Plate and Weld materials in order to establish that adequate toughness .

common rail cummins compression tester

Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. Hobart Brothers explains the process behind the charpy impact test, a key indicator of the toughness of weld metal.

Charpy impact test results are measured in joules, the SI unit for energy. This is simply the amount of work performed by a 1-newton force pushing a sample by 1 m in the direction of the force. This value can be used to calculate the impact energy in J/m2 by dividing the joule value by the sample's cross-sectional area at the sample notch. Filler metals undergo rigorous testing to ensure they provide proper impact toughness to endure rapid loading, extreme temperatures or other stressors. The C.Download Table | Charpy Impact Test Results for the Weld Metals. from publication: Low temperature impact toughness of structural steel welds with different welding processes | Influence of .

The Charpy V-Notch test is the welding industry’s most common method of measuring a weld’s toughness and involves multiple steps — from preparing a test plate to cutting and baking sample blanks, adding a notch to the . The Izod test is rarely used these days for weld testing having been replaced by the Charpy test and will not be discussed further in this article. . The previous article looked at the method of Charpy-V impact testing and the results that can be . The Charpy impact test behavior of base metal, weld metal, and heat‐affected zone for 6061‐T6 and 7075‐T651 aluminum alloy welds was analyzed. The Charpy V-notch Test: Measuring Impact Toughness in Filler Metals. The Charpy V-notch (CVN) test is one of several tests used to determine impact toughness in filler metals and is considered to be the industry standard. The equipment needed to conduct the test consists of a hammer located at the end of a pendulum (see Figure 1). After the .

compressed air cylinder testing near me

The purpose of this study was to evaluate fracture resistance in AISI 304. The J-R curve was constructed from data, which resulted from an impact test by Charpy Impact machine equipped with high-speed sampling rate data acquisition equipment. The critical values of fracture resistance in fusion zones (FZ), high temperature heat affected zones (HTHAZ), low . The Charpy V-notch test is also a standard laboratory test for welded joints. According to European Standards for destructive tests on welds in metallic materials, the impact test specimens are cut out so that they are perpendicular to the weld and parallel to the surface of the test piece. Prediction of Charpy impact toughness of steels, especially that of weld heat-affected zone (HAZ) is a difficult task. • Charpy impact test for a variety of steel weld HAZ samples was conducted to validate the computational model. • The proposed model can predict Charpy transition behavior from microstructural parameters only, with good . Standard E 23, ―Standard Test Methods for Notched Bar Impact Testing of Metallic Materials‖. In 1901, a French researcher named Charpy published his work—the second publication in the world on pendulum machine testing—on notched bar pendulum impact tests [2]. Charpy’s tests used a pendulum impact machine based on the design developed .

The influence of strength mismatch in a dissimilar steel joint on the Charpy absorbed energy was numerically analyzed on the basis of the Beremin model. The toughness correction ratio γCVN was defined as the ratio of the Charpy absorbed energy of a dissimilar steel joint specimen to that of a homogeneous specimen under the same Weibull stress. The .4 • Rapid adiabatic heating of test samples during Charpy impact testing at ultra-low temperatures makes current Charpy testing requirement invalid for ensuring material toughness . • Any sort of testing in liquid helium is difficult to accomplish, expensive, and not readily available. • Testing in LN2 has not been demonstrated to shed light on properties at -452F.For example, in welding and pressure vessel manufacturing, adherence to ASME Charpy impact test requirements is essential to guarantee the durability and safety of the final product. Toughness is especially important in metals that experience a ductile-to-brittle transition as temperatures drop.

charpy test results

webDiscutir qualquer tema sobre Fortune Gems com outros jogadores, partilhar a sua opinião e obter respostas às suas questões. Experimente slot Fortune Gems online e .

weld charpy impact test|charpy hardness test